Top Uses of Flexible Plastic Tubing in Various Industries?

Flexible plastic tubing plays a crucial role across numerous industries, including healthcare, manufacturing, and agriculture. Dr. Emily Thompson, an expert in polymer applications, states, “The versatility of flexible plastic tubing allows for innovative solutions that enhance efficiency and safety.” This insight underscores the material's significance in modern operations.

In the medical field, flexible plastic tubing is vital for the transportation of fluids and gases. Hospitals rely on it for IV lines and oxygen delivery. In manufacturing, it facilitates the movement of liquids and granules. Various processes depend on the durability and adaptability of this tubing.

However, challenges exist. Quality control is paramount, as poor materials can lead to leaks or failures. Additionally, the environmental impact of plastic waste requires reflection and improvement. Industries must balance functionality and sustainability when utilizing flexible plastic tubing.

Advantages of Flexible Plastic Tubing in Industrial Applications

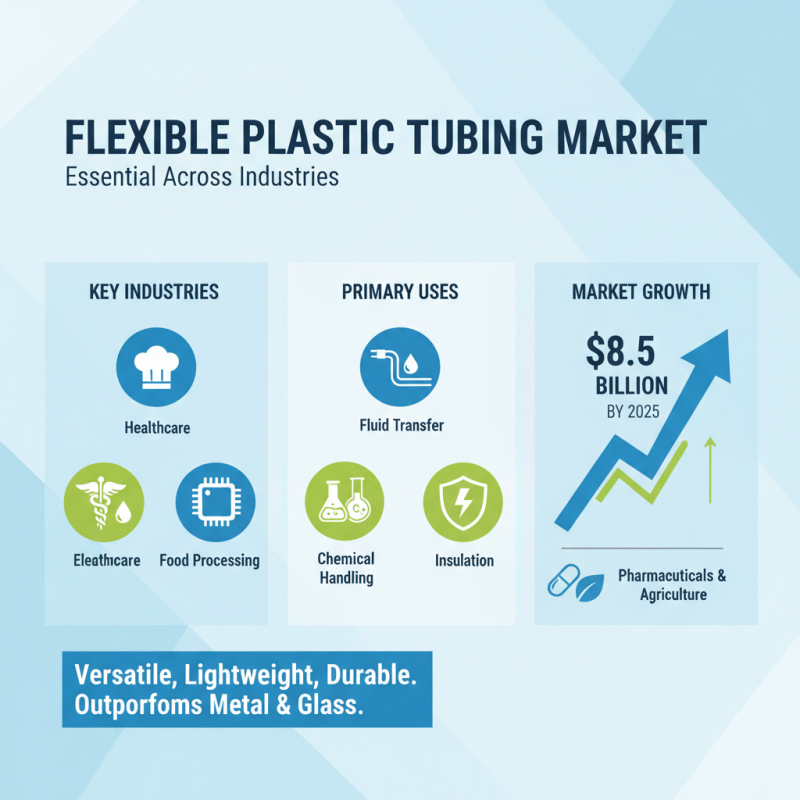

Flexible plastic tubing has become essential in various industries, including healthcare, food processing, and electronics. The versatility of these tubes makes them ideal for fluid transfer, chemical handling, and even insulation. According to a recent report, the global market for flexible plastic tubing is expected to reach $8.5 billion by 2025, driven by rising demand in sectors such as pharmaceuticals and agriculture. Its lightweight yet durable nature often outperforms traditional materials like metal and glass, positioning it as a preferred choice.

One significant advantage is the material's resistance to corrosion and impacts. This durability is crucial in environments where harsh chemicals are common. However, the longevity of flexible plastic tubing can also present challenges. Improper disposal can lead to environmental concerns. The industry must find a balance between performance and sustainability. Furthermore, while these tubes are designed for various temperatures, extreme conditions can still compromise their integrity. Regular assessments are necessary to ensure they are fit for high-stress applications.

In the medical field, for instance, the use of flexible plastic tubing in IV systems has revolutionized how fluids are administered. Flow rates are easily adjustable, and the clarity of the material allows for quick visual checks. Yet, complications can arise from improper connections or contamination. This highlights the importance of thorough training for personnel handling such equipment. Investing in better quality control will mitigate these risks, ensuring safe usage across different scenarios.

Key Industries Utilizing Flexible Plastic Tubing

Flexible plastic tubing has become essential in various industries due to its versatility and durability. The medical sector relies on this tubing for medical devices. This includes IV lines and catheters. The lightweight nature allows easy handling, enhancing patient care.

In the agriculture industry, flexible tubing is vital for irrigation systems. It helps efficiently distribute water to crops. This method reduces waste and increases crop yields. However, improper installation often leads to leaks and inefficiencies, needing attention.

Manufacturing also benefits greatly from flexible plastic tubing. It is used for transporting fluids and gases. Industries like automotive utilize these tubes in cooling and fuel systems. Yet, there are concerns about the long-term effects of exposure to chemicals. Regular assessments are crucial to ensure safety and functionality.

Common Materials Used for Flexible Plastic Tubing

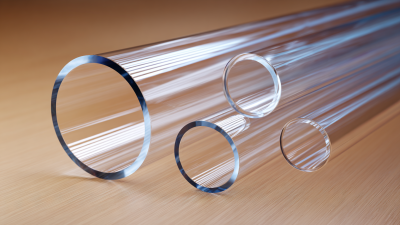

Flexible plastic tubing is widely used across various industries due to its versatility and durability. The most common materials for manufacturing these tubes include polyethylene, PVC, and polyurethane. Each of these materials offers distinct advantages based on the specific needs of the application. For instance, polyethylene is favored for its lightweight properties and chemical resistance.

Recent market reports indicate that polyethylene tubing accounts for a significant share of the flexible tubing market, attributed to its low cost and ease of manufacturing. PVC tubing also holds a strong position in the market, often used in construction and automotive applications. It's less flexible than polyethylene but offers excellent abrasion resistance. However, the environmental concerns associated with PVC production have sparked discussions about sustainable alternatives.

Polyurethane tubing is more specialized, known for its high elasticity and superior tear resistance. It's increasingly used in medical and food processing industries. However, the production cost can be a barrier for some applications. The industry must reflect on balancing cost and sustainability. As manufacturing techniques evolve, a push for bio-based materials is gaining traction, though challenges remain. These considerations shape the future of flexible plastic tubing in numerous sectors.

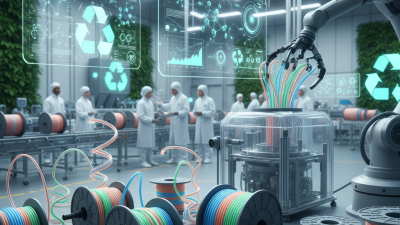

Innovative Applications of Flexible Plastic Tubing in Manufacturing

Flexible plastic tubing has become essential in manufacturing. It's lightweight and versatile. Many industries benefit from its use. For instance, in the automotive sector, these tubes can transport fluids under pressure. They are durable and can withstand various temperatures. Workers often handle them easily, making processes more efficient.

In the food industry, flexible plastic tubing plays a crucial role. It helps in transportation for liquids, such as juices or oils. These tubes maintain hygiene standards and prevent contamination. However, the challenge lies in ensuring they meet safety regulations. Sometimes, manufacturers overlook this aspect. This oversight can lead to serious issues.

Medical applications are another area where flexible plastic tubing shines. It's used in devices for delivering medications. These tubes must be precise and reliable. Yet, achieving consistency can be difficult. Quality control is essential, but sometimes standards slip. A minor error can have significant consequences in patient care.

Environmental Considerations in the Use of Flexible Plastic Tubing

Flexible plastic tubing has a versatile role across industries like food, pharmaceuticals, and construction. However, its environmental impact shouldn't be overlooked. Many products are single-use and often end up in landfills. This raises concerns about plastic pollution and its effects on wildlife. Companies must reflect on their packaging choices.

Recycling rates for flexible plastic are low. This is partly due to the difficulty in separating materials. Consumers often feel confused about disposal methods. Educating them is crucial. Innovations in biodegradable alternatives show promise, yet they require stricter industry regulations. More effort is needed to develop better recycling programs.

Environmental responsibility is essential in tubing production. Choices made today influence future sustainability. Companies need to balance utility and ecological impact. Developing sustainable materials could reduce harmful emissions. It's a complex journey, but worth pursuing for a healthier planet.

Top Uses of Flexible Plastic Tubing in Various Industries

This bar chart illustrates the various applications of flexible plastic tubing across different industries, highlighting their environmental considerations. The data points represent the estimated usage percentage of flexible plastic tubing in each industry.

Related Posts

-

2025 Top Trends in Flexible Plastic Tubing: Innovations and Applications

-

Top Trends in Rigid Plastic Tubing for 2025 What You Need to Know

-

How to Choose the Right Hard Plastic Tubing for Your Project Needs

-

How to Choose the Right Plastic Channel for Your Wiring Needs

-

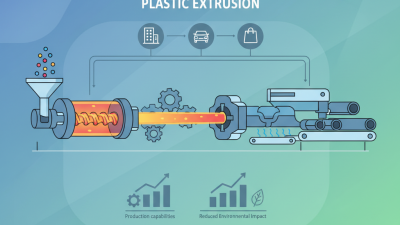

What is a Plastic Extruder and How Does it Work in Manufacturing Processes

-

How to Choose the Best Polycarbonate Tube for Your DIY Projects and Home Improvements