Innovative Techniques in Plastic Extrusion Transforming Manufacturing for the Future

The evolution of manufacturing processes has been significantly influenced by innovative techniques in plastic extrusion, a method that has revolutionized the production of plastic materials across various industries. According to a report by Grand View Research, the global plastic extrusion market is expected to reach USD 500 billion by 2025, growing at a CAGR of 4.3%. This growth is driven by the increasing demand for lightweight and durable materials in sectors such as automotive and packaging.

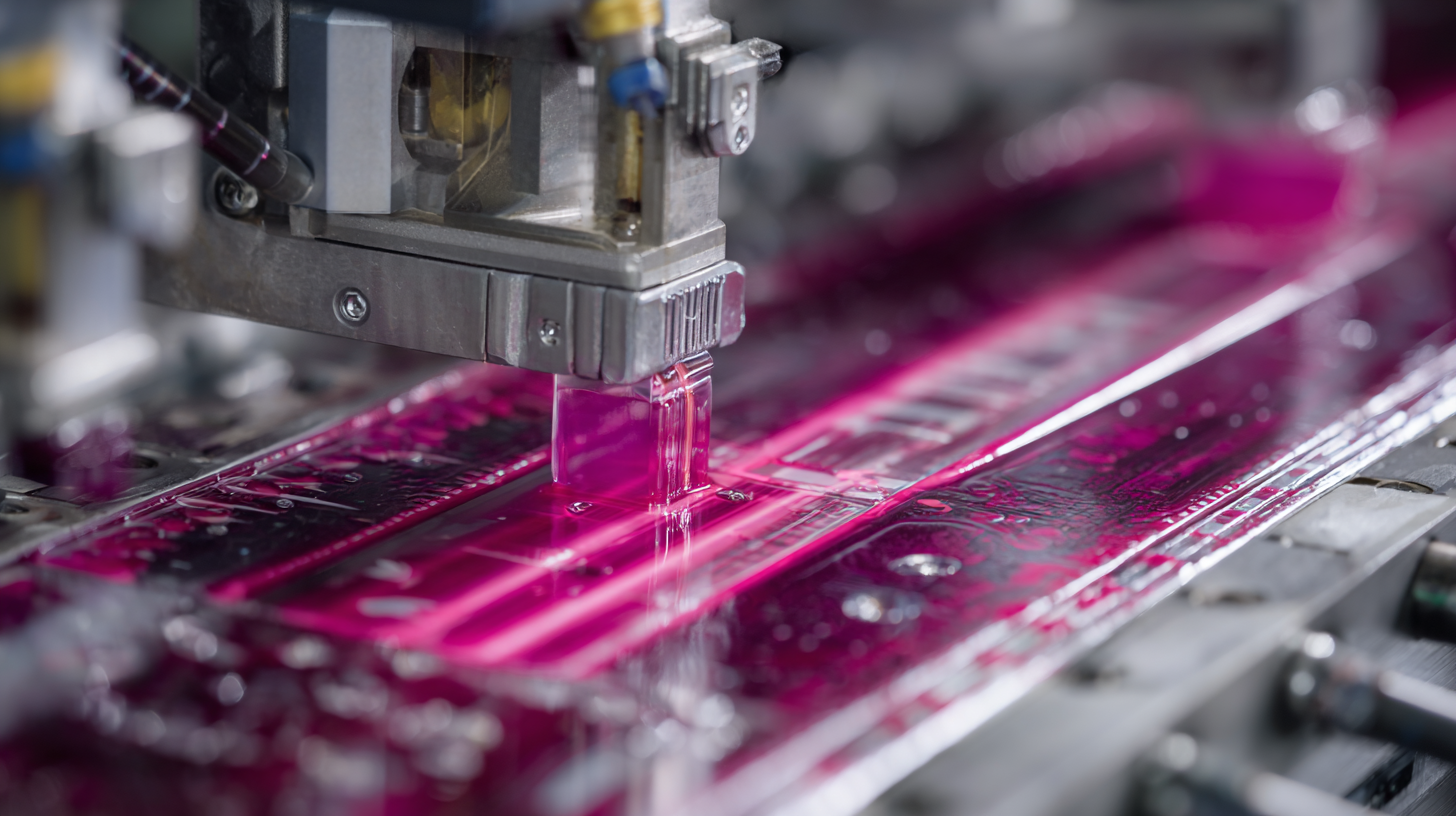

Advanced technologies in plastic extrusion, including co-extrusion and 3D printing capabilities, are not only enhancing productivity but also promoting sustainability through reduced waste and energy consumption. As manufacturers seek to adapt to evolving market needs, the integration of state-of-the-art techniques in plastic extrusion is set to play a crucial role in shaping the future of the industry, ensuring efficiency, increased output, and environmental responsibility.

Innovative Plastic Extrusion Techniques Driving Sustainability in Manufacturing

Innovative techniques in plastic extrusion are emerging as pivotal drivers of sustainability in manufacturing, reshaping the industry's approach towards environmental responsibility. Advanced extrusion methods now incorporate recycled materials, significantly reducing waste and reliance on virgin resources. By optimizing material flow and energy consumption during the extrusion process, manufacturers can enhance efficiency while minimizing their carbon footprint. This shift not only addresses ecological concerns but also meets the increasing consumer demand for sustainable products.

Moreover, technological advancements such as real-time monitoring and automation further enhance the sustainability of plastic extrusion. These innovations allow manufacturers to closely track production parameters and materials usage, leading to improved resource management and waste reduction. Additionally, employing bioplastics in extrusion processes represents a promising avenue for environmentally friendly manufacturing. As companies increasingly adopt these innovative techniques, the manufacturing landscape is set to evolve towards a more sustainable future, ultimately fostering a circular economy where materials are reused and emissions are minimized.

Innovative Techniques in Plastic Extrusion Transforming Manufacturing for the Future

This chart illustrates the projected adoption rate of innovative sustainable plastic extrusion techniques from 2021 to 2025, showcasing the industry's commitment to environmentally friendly manufacturing practices.

Advances in Digital Technologies Revolutionizing Plastic Extrusion Processes

The plastic extrusion industry is undergoing a significant transformation driven by advances in digital technologies. Smart manufacturing practices, such as the integration of Internet of Things (IoT) sensors and , are enabling manufacturers to optimize their extrusion processes. These technologies provide real-time data that helps identify inefficiencies and predict equipment failures before they occur. As a result, production lines are becoming more flexible and adaptive, allowing companies to meet the evolving demands of the marketplace while minimizing downtime.

Moreover, the use of advanced simulation software is revolutionizing the design and testing phases of plastic extrusion. By utilizing digital twins, manufacturers can create virtual representations of their processes, testing various scenarios and configurations without interrupting production. This capability not only reduces development times but also enhances the quality of the final products. As these digital technologies continue to advance, they promise to enhance precision, reduce waste, and lead to more sustainable practices within the plastic extrusion industry, paving the way for a smarter, more efficient manufacturing future.

Impact of Industry 4.0 on Efficiency and Precision in Plastic Extrusion

The emergence of Industry 4.0 is revolutionizing the landscape of plastic extrusion, bringing forth a new era characterized by enhanced efficiency and unparalleled precision. By integrating advanced technologies such as IoT (Internet of Things), big data analytics, and artificial intelligence, manufacturers can achieve real-time monitoring of production processes. This connectivity not only allows for immediate adjustments to be made in response to machine performance and material variations but also significantly reduces waste and energy consumption. As a result, the extrusion process becomes more sustainable and cost-effective.

Furthermore, the application of predictive maintenance techniques powered by AI algorithms ensures that machinery operates optimally, minimizing downtime and reducing maintenance costs. The synergy between automation and human oversight leads to smarter production lines, where operators can focus on strategic decision-making rather than repetitive tasks. As digital twins and simulations become commonplace, manufacturers can refine their extrusion processes in virtual environments before implementing changes in the real world. This proactive approach enhances product quality and accelerates the time-to-market for new materials and designs, solidifying Industry 4.0’s transformative impact on the plastic extrusion sector.

Innovative Techniques in Plastic Extrusion Transforming Manufacturing for the Future - Impact of Industry 4.0 on Efficiency and Precision in Plastic Extrusion

| Technique | Description | Efficiency Improvement (%) | Precision Improvement (%) | Adoption Year |

|---|---|---|---|---|

| Smart Sensors | Integration of sensors for real-time monitoring of extrusion parameters. | 15% | 20% | 2021 |

| Predictive Maintenance | Using data analytics to predict equipment failures. | 25% | 30% | 2020 |

| AI Optimization | Applying machine learning algorithms to enhance process parameters. | 30% | 25% | 2019 |

| 3D Printing Integration | Combining extrusion techniques with additive manufacturing. | 40% | 35% | 2022 |

| Real-time Quality Control | Automated inspection systems to ensure product quality during production. | 20% | 40% | 2023 |

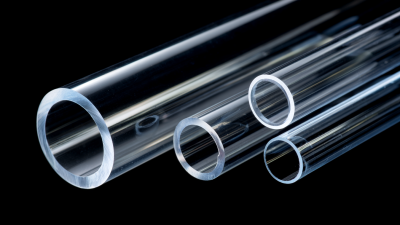

Emerging Materials and Their Role in the Future of Plastic Extrusion Technology

Emerging materials are significantly reshaping the landscape of plastic extrusion technology, driving innovations that enhance performance and sustainability. According to a recent report by Allied Market Research, the global bioplastics market is expected to reach $411 billion by 2027, growing at a CAGR of 20.5%. This surge is a testament to the increasing emphasis on environmentally friendly materials, such as polylactic acid (PLA) and polyethylene terephthalate (PET), which offer a lower carbon footprint compared to traditional plastics. These materials enable manufacturers to meet stricter regulations and consumer demand for sustainable products while maintaining high-quality extrusion processes.

Moreover, advancements in composite materials are further revolutionizing plastic extrusion. A study published by MarketsandMarkets indicates that the composite materials market is projected to grow from $85.4 billion in 2023 to $113.7 billion by 2028, driven by their lightweight, durability, and enhanced mechanical properties. These composites, often incorporating natural fibers or recycled content, are increasingly adopted in sectors such as automotive and packaging. By integrating innovative materials, manufacturers can enhance product characteristics while also reducing waste, reflecting a broader commitment to sustainability in the plastic extrusion industry.

Market Trends and Projections for the Global Plastic Extrusion Industry by 2025

The global plastic extrusion industry is poised for significant growth as market trends indicate a robust increase in demand. By 2025, the market size is expected to rise to approximately $8.199 billion, driven by the expanding applications of plastic in various sectors. This growth trajectory presents a transformative opportunity for manufacturers to adopt innovative extrusion techniques that enhance efficiency and reduce production costs. The increasing integration of advanced technologies in extrusion processes will likely lead to improved product quality and sustainability.

Furthermore, the ongoing shift towards sustainable packaging solutions is a key driver influencing market dynamics. The plastic packaging sector is projected to grow substantially, from $3.955 trillion in 2024 to $5.225 trillion by 2031, indicating a compound annual growth rate of 4.06%. This surge highlights the necessity for manufacturers to invest in modern extrusion technologies that not only meet the demands for higher production volumes but also align with environmental standards. As the industry evolves, companies that embrace these innovative techniques will not only enhance their competitiveness but also contribute to a more sustainable future for plastic manufacturing.

Related Posts

-

Understanding the Latest Innovations in Plastic Extruder Technology for Efficient Production

-

Exploring the Benefits of Plastic Channels in Modern Infrastructure Development

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions

-

Exploring the Benefits of Plastic Hinges: Durability and Cost-Efficiency in Modern Applications

-

Exploring the Versatility of Polycarbonate Tubes: Innovations in Design and Application

-

Unlocking the Benefits of PVDF Tubing: Why It’s the Future of Industrial Solutions