How to Choose the Best Polycarbonate Tube for Your DIY Projects and Home Improvements

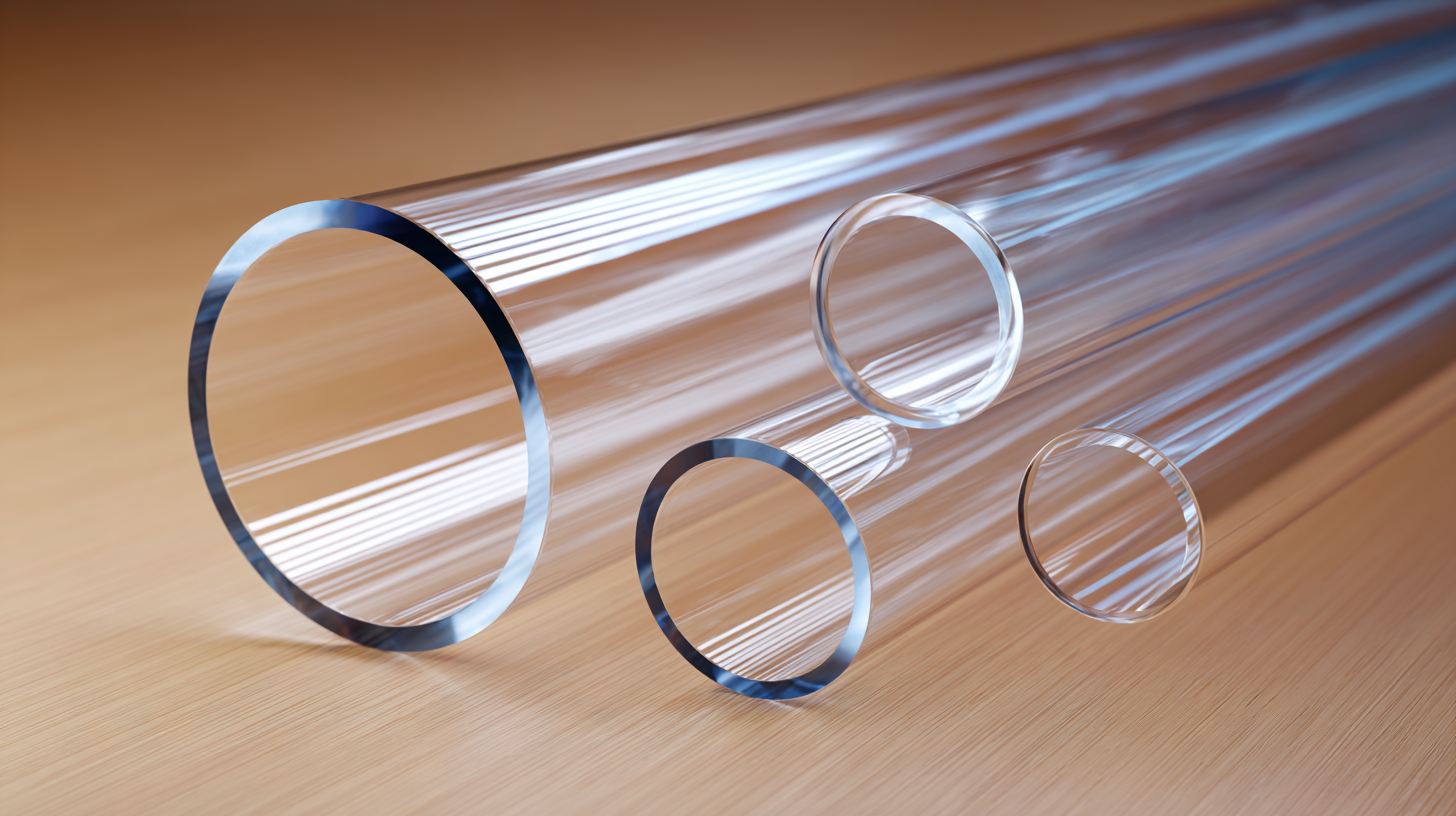

When embarking on DIY projects and home improvements, selecting the right materials is crucial to achieving optimal results. One such versatile material that has gained popularity among DIY enthusiasts is the polycarbonate tube. Known for its durability, impact resistance, and light transmission properties, polycarbonate tubes are ideal for a variety of applications, ranging from greenhouse construction to custom lighting solutions.

However, with numerous options available in the market, it can be overwhelming to determine which polycarbonate tube best suits your needs. This guide aims to simplify the decision-making process by highlighting key factors to consider, such as thickness, diameter, and UV resistance. Whether you're a seasoned DIYer or just starting out, understanding how to choose the best polycarbonate tube can enhance your projects and ensure long-lasting results.

Understanding Polycarbonate Tube Types and Their Features

When selecting a polycarbonate tube for your DIY projects, understanding the different types and features is crucial. Polycarbonate tubes can be categorized mainly into extruded and molded varieties. Extruded tubes are created by forcing melted polycarbonate through a die, resulting in uniform thickness and length, making them ideal for applications requiring consistent dimensions. Molded tubes, on the other hand, are produced by pouring melted resin into a mold, which allows for custom shapes and sizes. This flexibility is advantageous for specialized projects where unique dimensions or configurations are necessary.

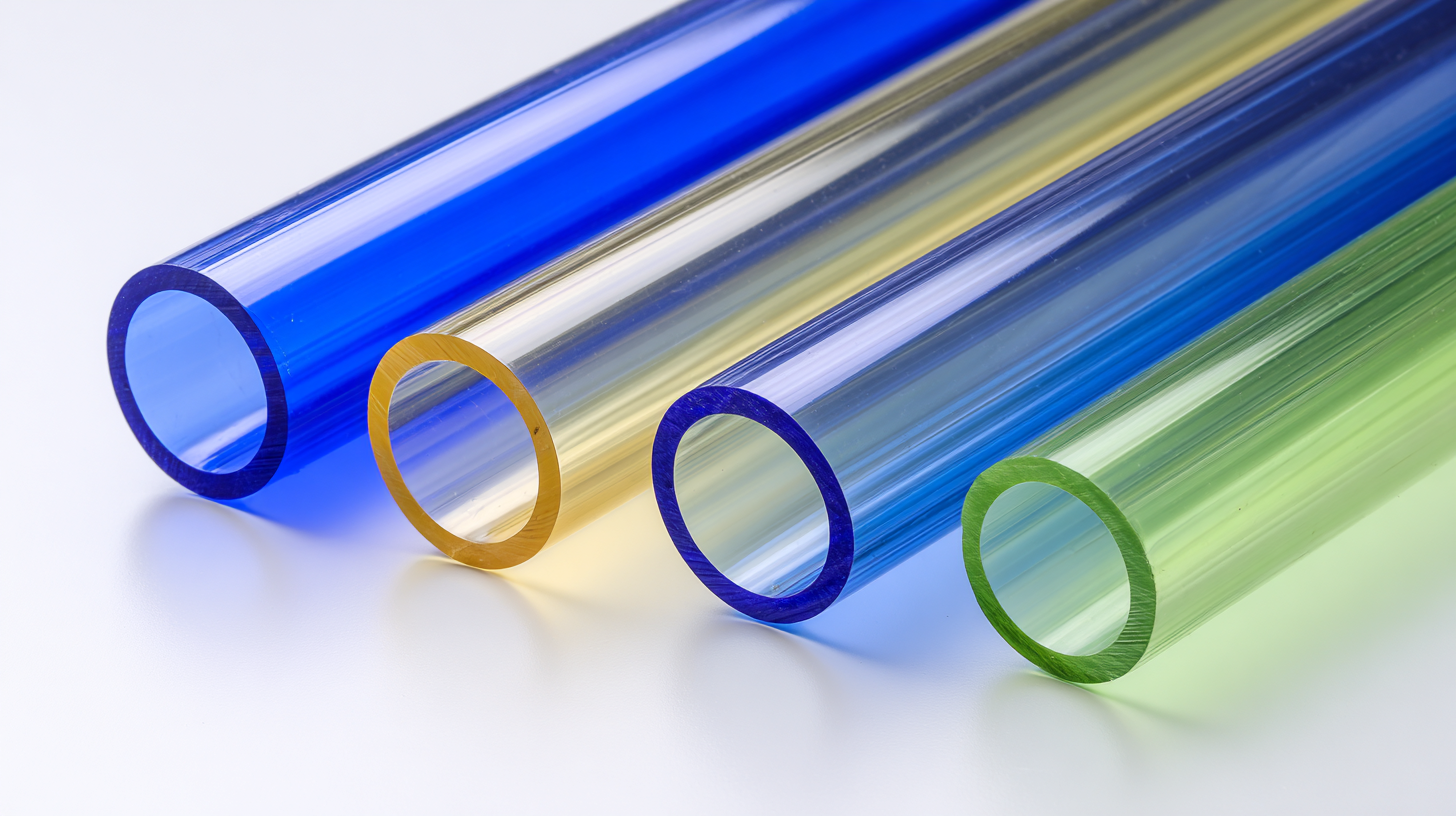

Another important feature to consider is UV resistance, which can significantly impact the longevity of your project, especially for outdoor applications. Many polycarbonate tubes are treated with UV inhibitors, protecting them from the harmful effects of sunlight while maintaining clarity. Additionally, evaluating the thermal insulation properties of the tubes is essential for projects that require temperature regulation.

Different grades of polycarbonate offer various levels of heat resistance, which can be beneficial when creating structures exposed to extreme weather conditions. By grasping these types and features, you can make a more informed decision to suit your specific needs.

Key Factors to Consider When Selecting Polycarbonate Tubes

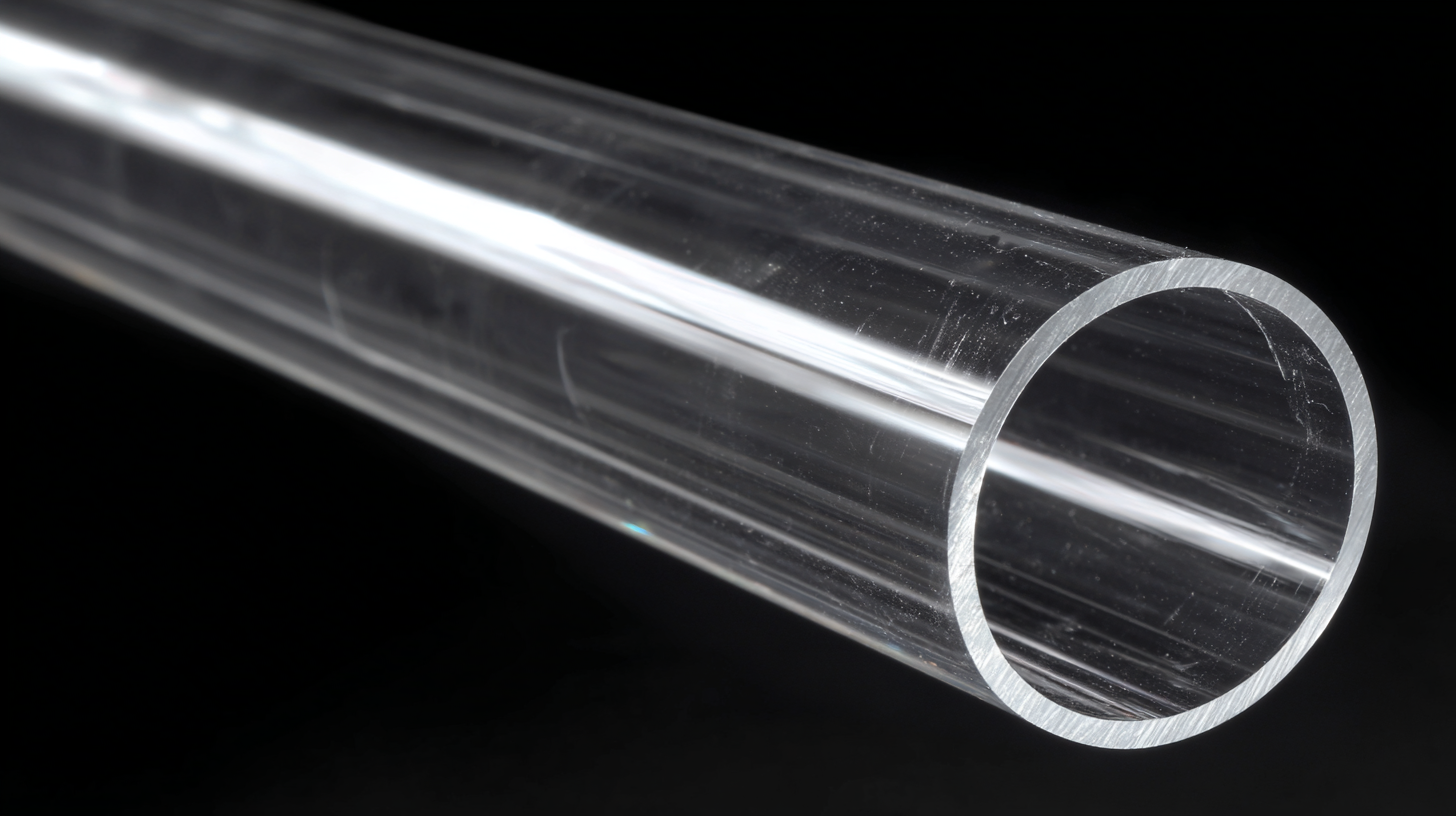

When selecting polycarbonate tubes for your DIY projects and home improvements, there are several key factors to consider. First and foremost, the thickness of the tube can significantly impact its durability and application. Thicker tubes are more resistant to impact and can withstand harsher environmental conditions, making them ideal for outdoor use. On the other hand, thinner tubes may be suitable for indoor projects where flexibility and lightweight options are preferred.

Another important factor is the tube's UV resistance. If your project involves exposure to sunlight, opt for UV-treated polycarbonate tubes to prevent yellowing and degradation over time. This will ensure that your projects maintain their aesthetic appeal and structural integrity longer than untreated alternatives.

Tip: Always consider the intended purpose of the tube. For plumbing or furniture projects, transparency and dimensional stability may be crucial, while for lighting projects, a frosted or patterned tube may enhance diffusion of light.

Tip: Lastly, don't forget to check for compatibility with adhesives and fittings. Certain types of polycarbonate may bond better with specific adhesives, impacting the overall success of your project. Always read product specifications and perform a small test if you're unsure about compatibility.

Common Applications for Polycarbonate Tubes in DIY Projects

Polycarbonate tubes are an excellent choice for a variety of DIY projects due to their durability and versatility. Common applications include making protective barriers, creating greenhouse structures, and crafting custom drink dispensers. Their impact resistance and lightweight nature make them ideal for both indoor and outdoor uses, enhancing the functionality of your projects without adding unnecessary weight.

When working on your projects, consider using a high-quality adhesive that is specifically designed for plastic. Each type of glue has distinct properties, so choosing the right one can make a significant difference in the longevity and strength of your creations. For instance, some adhesives work best under heat, while others are formulated to resist moisture—important factors depending on the intended use of your polycarbonate tube creation.

Tip: Always check the compatibility of the adhesive with polycarbonate before application. Additionally, ensure that all surfaces are clean and dry to achieve the best bond. For projects involving heat exposure, experimenting with a heat gun can also provide a professional finish, giving you greater control over the shaping and alteration of the material.

Comparing Polycarbonate Tubes to Other Materials for Home Improvements

When considering materials for home improvements and DIY projects, polycarbonate tubes stand out for their unique properties when compared to other materials such as PVC and glass. Polycarbonate is known for its exceptional impact resistance and heat stability, allowing it to withstand harsh environmental conditions. According to industry reports, polycarbonate can absorb up to 250 times more impact energy than glass and offers excellent UV resistance, making it a more durable option for outdoor applications.

In contrast, while PVC is lightweight and cost-effective, it lacks the rigidity and heat resistance of polycarbonate. Recent studies indicate that although PVC might be less expensive upfront, the longevity and performance of polycarbonate can lead to lower costs over time, as it requires less frequent replacement. Additionally, glass, despite its aesthetic appeal, is more fragile and can pose safety risks, particularly in areas with high foot traffic or potential for impact. Therefore, when selecting the best material for your DIY projects, polycarbonate tubes not only provide superior performance metrics but also align with a focus on long-term value and safety.

Best Practices for Cutting and Installing Polycarbonate Tubes in Projects

When working on DIY projects involving polycarbonate tubes, proper cutting and installation techniques are essential. The first step in cutting polycarbonate tubes is to ensure you have the right tools. A fine-toothed saw or a specialized tube cutter can provide clean cuts without cracking the material. It's important to mark your cutting line clearly and to support the tube adequately while cutting. Taking your time and using steady pressure will help you achieve a precise cut.

Once the tubes are cut to the desired lengths, the next step involves installation. Polycarbonate tubes can be secured using brackets designed for circular shapes, or simply by using silicone adhesive if a more permanent fixture is needed. When installing, it's crucial to account for expansion and contraction due to temperature changes. Leaving a small gap at the ends can prevent warping. Furthermore, consider the orientation of the tubes, especially if they will be exposed to sunlight, as UV protection and alignment can significantly affect durability and performance in outdoor setups.

Related Posts

-

Exploring the Benefits of Plastic Channels in Modern Infrastructure Development

-

Exploring the Benefits of Plastic Hinges: Durability and Cost-Efficiency in Modern Applications

-

Unlocking the Benefits of PVDF Tubing: Why It’s the Future of Industrial Solutions

-

Unlocking the Benefits of Custom Tubing: A Game Changer in Modern Engineering Solutions